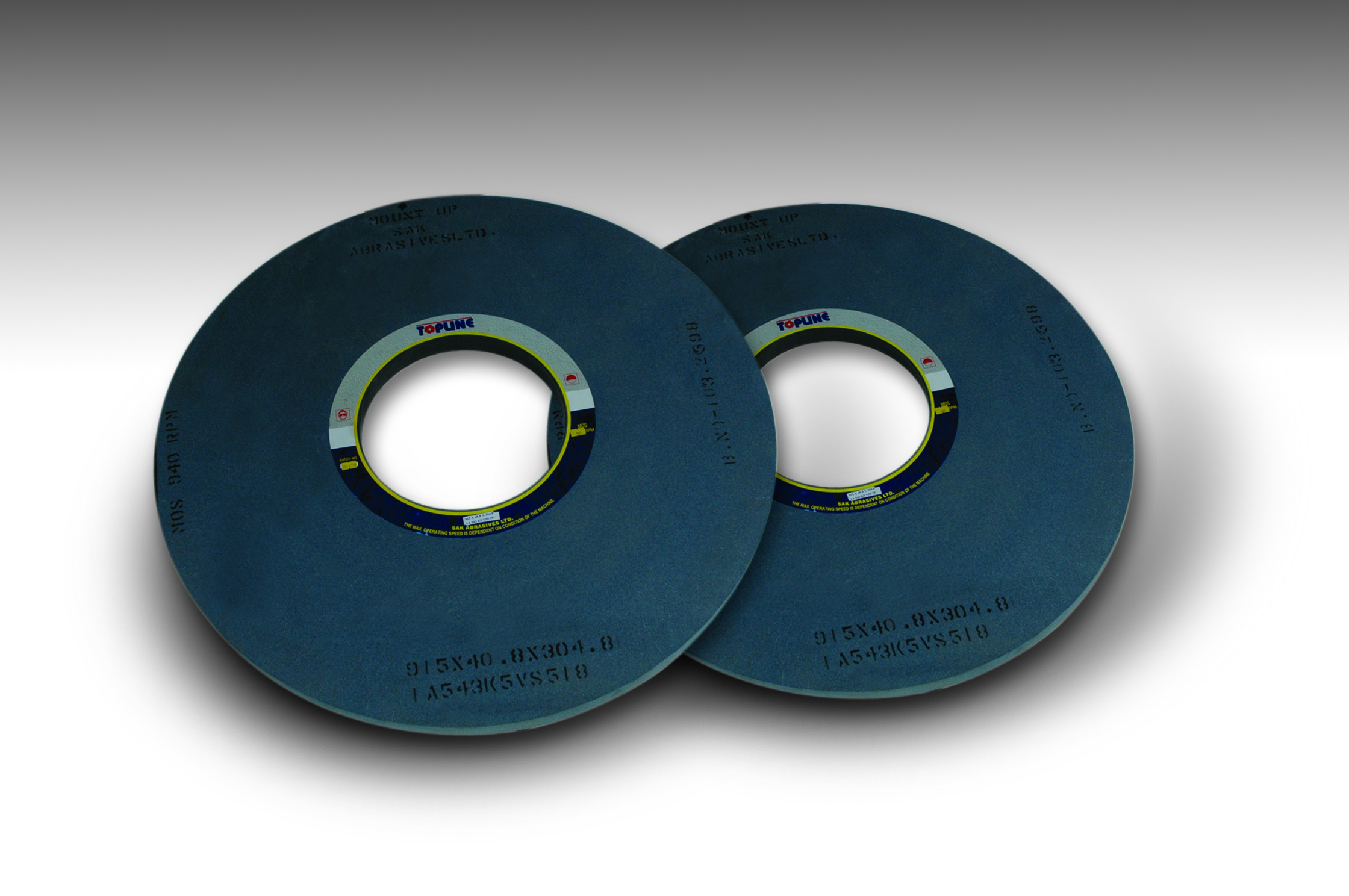

Cylindrical grinding wheel

Generate perfectly sized parts in a flash

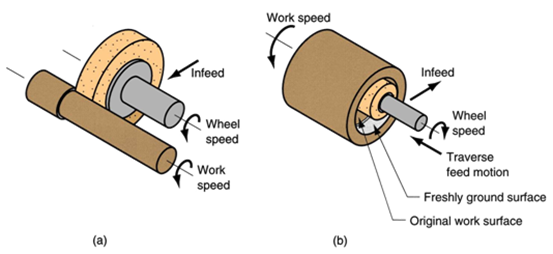

Used in O.D. grinding of gear shafts, splined shafts, transmission shafts, valves, plunger pins, eye bolts, bearing races, etc. In this operation, the external or internal cylindrical surface of a work piece is ground. In external cylindrical grinding, or centre-type grinding, the work piece rotates and reciprocates along its axis although for large and long work parts, the grinding wheel reciprocates.

In internal cylindrical grinding, a small wheel grinds the inside diameter of the part. The work piece is held in a rotating chuck in the headstock and the wheel rotates at very high rotational speed. In this operation, the work piece rotates and the grinding wheel reciprocates.

(a) External Grinding; (b) Internal Grinding

Market solutions:

Automotive: Roughing

Bearing industry: construction

General engineering: soft steel, hardened steel, chilled cast iron, non ferrous material

- Tools industry

Advantages:

Advantages:

Increased productivity due to higher stock removal and freer cutting

Fine surface finish

Reduced rework

Reduced loading and dressing frequency