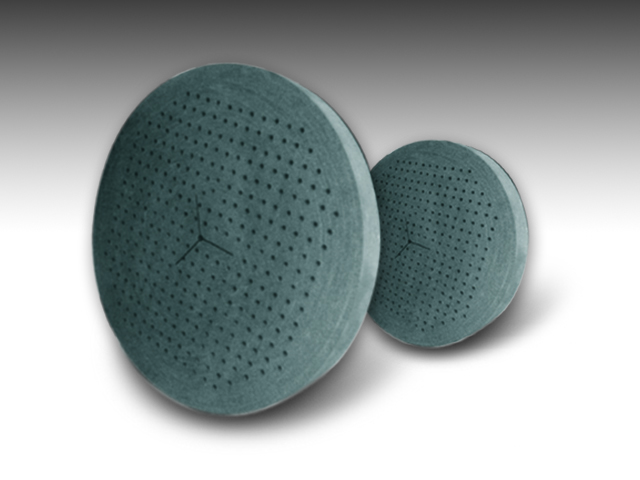

Disc Grinding- Surface Grinding Specials

Specially designed nut-inserted wheels offering better control and optimum performance on different materials.

Disc Grinding is similar to surface grinding, but with a larger contact area between the disc and the work piece. Disc grinders are available in both vertical and horizontal spindle types. Disc grinders are capable of achieving especially fine tolerances. It is a special surface grinding application used on bearing and piston-ring faces, spring ends, valve plates, etc.

Market solutions:

Automotive

Bearing: Bearing Rings, cylindrical rollers and needles, spherical rollers

General Engineering

Foundry and fabrication

Advantages:

Advantages:

Improved control over dimensioning

Higher productivity through reduced dressing frequency

Honeycomb structure enabling better chip clearance, higher depth of cut and cooler cutting