ABOUT US

Established in 1997, Sak Abrasives has gained international recognition as a world – class producer of bonded, coated and super abrasive products. The high quality finish and cost – effectiveness of our products have made us the preferred choice of many leading corporations in India and the USA. The company’s well-equipped R&D team, staffed with highly experienced engineers, enables the development of grinding wheels catered to customer requirements, along with continuous analysis and performance tests in support of product development.

PRODUCTS

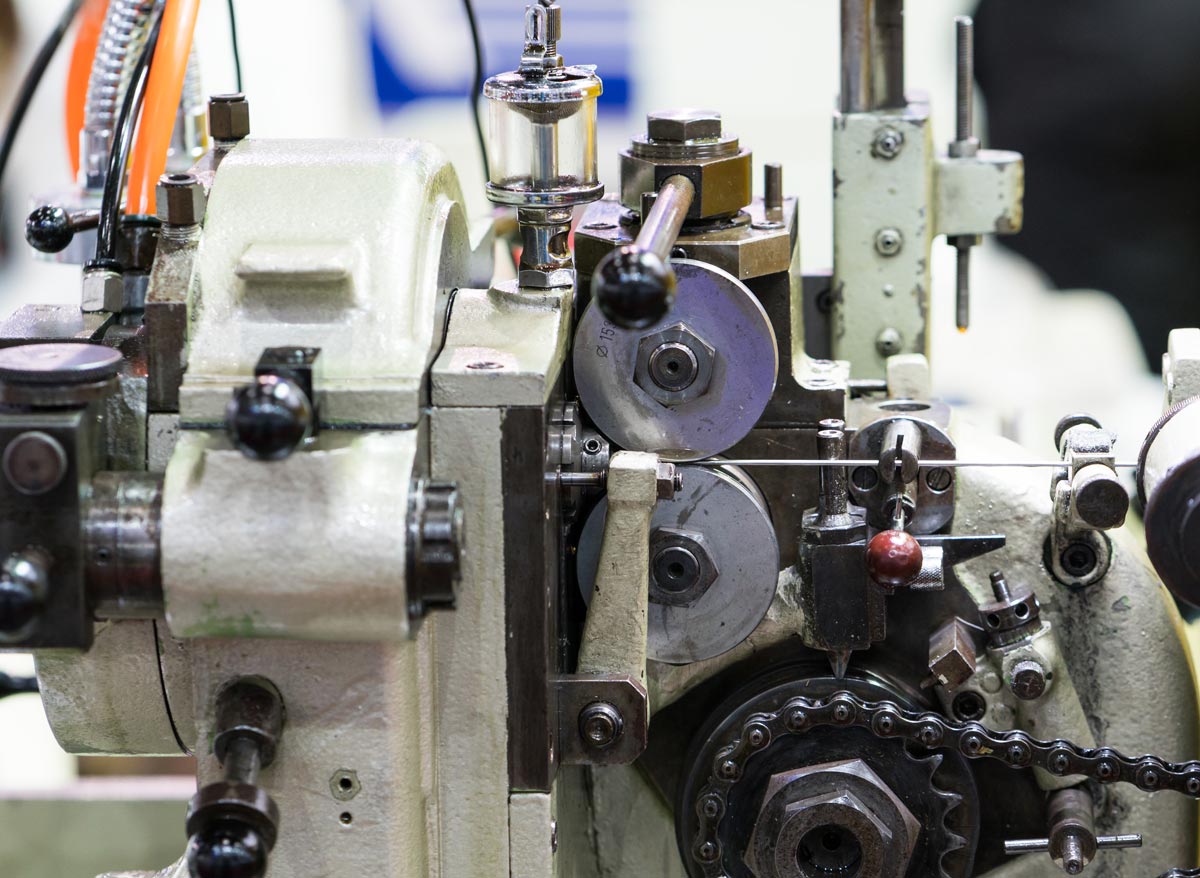

Abrasives are materials, often minerals that are used to shape or finish a work piece through rubbing which leads to a part of the piece being worn away by friction and these abrasive processes are important because it can be used on all types of materials.

Super Abrasives

Super abrasives are used for the most precision grinding. They are known for their extraordinary hardness, wheel life & exceptional performance.

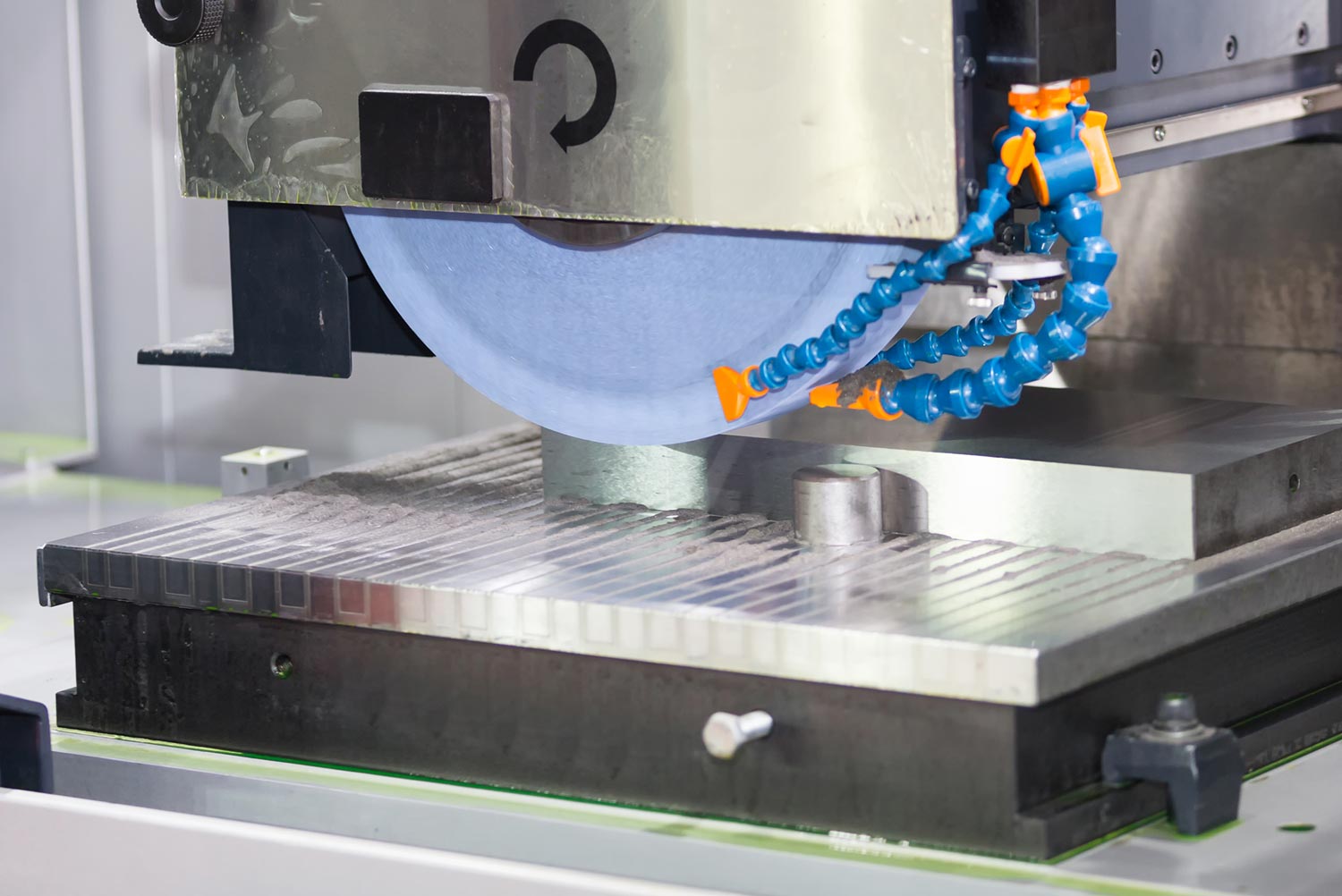

Bonded Abrasives

Bonded abrasives are a mixture of filler, abrasive grains and a bonding component. The bonding component can either be vitrified or resinoid.

Special Products

Super Abrasives, Bonded Abrasives and Coated Abrasives are the three types of abrasives, we manufacture. We have mentioned the variousSUCCESS STORIES

Ductile Iron Pipe Manufacturer

A Ductile Iron Pipe Manufacturer was using our conventional product, 500*5*38 COW wheel with Al- Oxide and buying approximately [...]

A Tool manufacturer in Netherlands

A tool manufacturer in Netherlands, ordered Topline abrasives from India, used in a 5-Axis Tool Grinding Machine and compared it [...]

Air compressors & pneumatic tools

A customer who is a manufacturer of air compressors and pneumatic tools, was using a competitor abrasive for a WMW [...]

Automobile Manufacturer

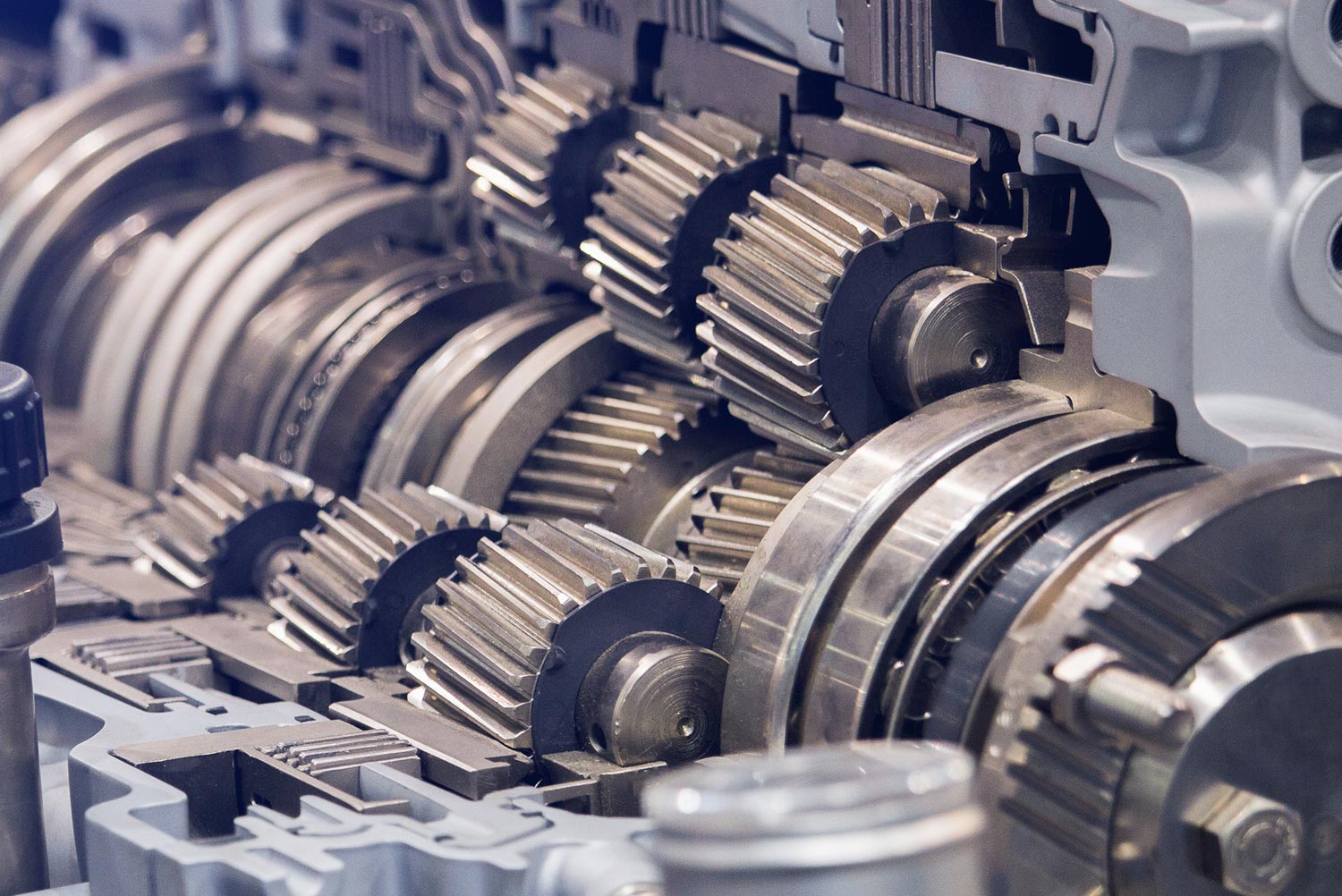

An automobile manufacturer was using a competitor’s abrasive for crank pin grinding. The dressing frequency was every two pins and [...]

BLOGs

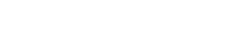

Topline Toolroom Grinding Wheels: Precision Sharpening & Surface Grinding

Topline Toolroom Grinding Wheels are engineered to provide exceptional precision, durability, and surface quality in critical grinding operations. Specifically [...]

Topline Cylindrical Grinding Wheels: Precision and Performance for Every Industry

Topline Cylindrical Grinding Wheels are designed to deliver superior performance across various industries, ensuring consistent quality and productivity. Cylindrical grinding [...]

Maximizing Efficiency with Topline Centreless Grinding Wheels

In the industry of precision manufacturing, centreless grinding stands out as a critical procedure for obtaining remarkable accuracy and smooth [...]

Topline Snagging Wheels: Abrasive Solutions for Tough Jobs

Snagging wheels are abrasive equipment used for heavy-duty material removal, particularly in industrial environments. Topline wheels are extremely efficient at [...]